For a lot of electronics enthusiasts and DIYers, hand-soldering SMT components can be a great challenge. And given the trend of component miniaturization, a lot of ICs no longer come with DIP packaging. Soldering such small components by hand without proper equipment (e.g. SMD hot air rework station) can be extremely difficult for beginners. The folks at SchmartBoard were kind enough to send me a few of their SMT prototyping boards to play with. So I decided to try them out to see how their proto-boards stack up with some of the alternatives on the market.

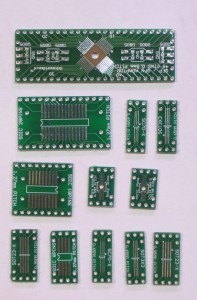

The boards I received came with a good variety, with the pitch ranging from 1.27mm for the SOIC adepters all the way down to the 0.5mm for theDFN adapters (see picture below). The construction quality of these PCBs are excellent, and it is probably the best among all the proto-boards that I have used. Of course, this is somewhat to be expected given the price premium for this boards.

Originally I had hoped to try out the 0.5mm DFN adapter first. But since I do not have any 0.5mm DFN chips on hand I decided to try out the SOT23 adapter first instead. While the pitch for SOT23 is relatively large (0.95mm), the actual SOT23 chips are usually quite small, so in my opinion this is still a good candidate for testing out the level of effort needed to mount and solder the chip.

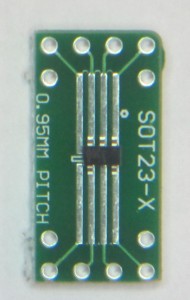

The chip I used is FAN5333A, an LED driver IC, which comes in the typical tiny SOT23 package (see picture below). According to instructions SchmartBoard provided, the soldering tip needs to be smaller than the trace width due to the grooved design of the traces. This is slightly different then soldering other adapter boards. I tend to use iron tips that are slightly wider than the traces with standard adapter boards so that the traces can be heated up more quickly and at the same time the chance of trace bridging is kept at minimum. But given the uniqueness of the board design, I switched for a smaller (0.8mm) chisel-tip.

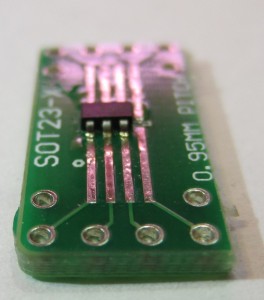

This grooved-trace design — a key selling feature of the SchmartBoard — makes it very easy to place the chip onto the board. Chips can be precisely placed on the board prior to soldering. I was pleasantly surprised at how easy it really was to properly align a tiny chip on the SchmartBoard. The leads fit into the pre-etched grooves with just a little bit of a wiggle. In this close-up picture I took below you can see how the pins fit in the groove.

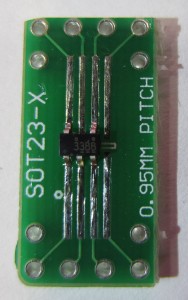

The actual soldering is almost effortless as well. Following the instructions, I used a little bit of water-soluble flux on the traces and set the tip temperature to be 400F (SchmartBoard uses unleaded solder, so the soldering temperature needs to be significantly higher than that using leaded solder). And using a linear motion starting from the outer edge of each trace, I pushed the soldering tip towards each lead. Since the traces are pre-soldered, no additional solder is needed. When the iron tip moves towards the chip, the solder melts and gets pushed towards the lead and forms beautiful solder joints. The picture below shows the board after the chip is soldered on.

And here is another picture of the soldered board:

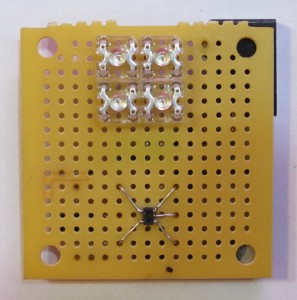

Of course, SOT23 chips can be soldered by hand without using an SMT adapter as well. So as an alternative, you could do what I did in the picture below (a FAN5333A LED driver board) by gluing the chip onto the board and using thin wires to breakout the leads. Of course, this method takes considerably more time and practice.

For those who have been reading my blog, you know that I like the challenges of soldering these fine pitched chips by hand without resorting to any special tools (I, II, III). But for people who just want to make sure that their circuit works and do not have the interests or patience to fiddle around with these tiny chips, a high quality SMT adapter becomes a must. There are other SMT adapters out there. But without the grooves, you may find it much harder doing the chip alignment and soldering correctly. Also, the quality of the SchmartBoard is arguably much higher than many cheaper priced alternatives. SchmartBoard is designed to handle the higher soldering temperature required with the unleaded solder. As a result, the traces do not come off easily even when abused.

Overall, I would give a big thumbs up to the SchmartBoard.